- This topic is empty.

-

AuthorPosts

-

11/08/2025 at 14:42 #4449

Many customers often encounter issues such as suboptimal detection results, false rejections, or missed rejections when using metal detectors for foreign body detection. These issues not only impact production efficiency but also pose food safety risks. These issues are often closely related to the equipment's detection sensitivity. This series will introduce nine common factors that affect metal detector sensitivity, aiming to provide a reference for optimizing detection strategies.

1. Detection Channel Size

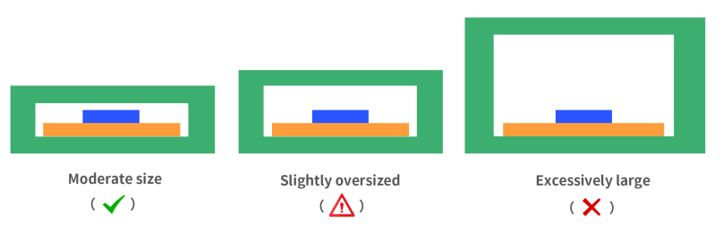

All other conditions remaining unchanged, a metal detector's detection sensitivity is strongly influenced by its channel size. Generally, larger openings result in poorer detection, and smaller openings improve detection. Therefore, if the opening size matches the product size and does not affect product flow, choose a metal detector with a smaller opening for higher detection accuracy. See the figure below for details.

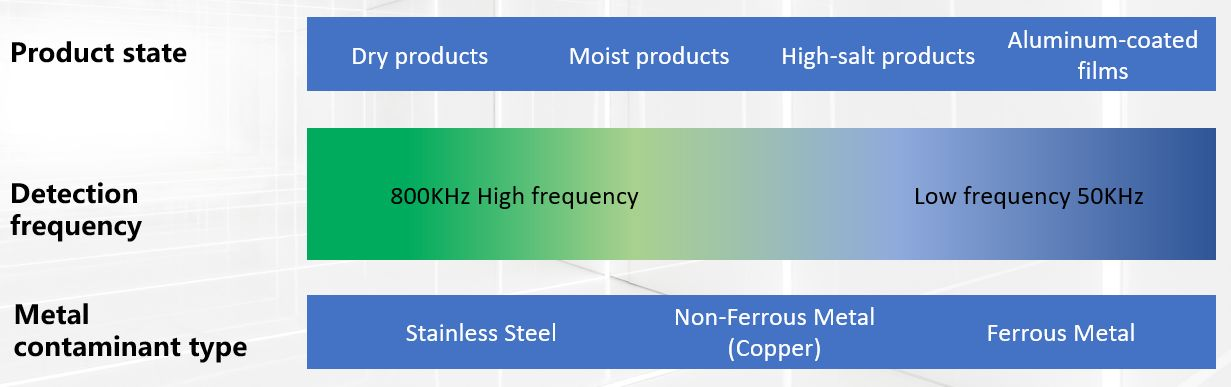

2. Metal Detector Frequency

The frequency of a metal detector is closely related to its metal foreign body detection sensitivity. Metal detectors are classified into single-frequency and multi-frequency types. Single-frequency metal detectors have a single, fixed frequency and a higher detection rate for ferrous foreign bodies. Multi-frequency metal detectors have multiple built-in frequencies, allowing flexible switching based on the material and size of the inspected item, accurately identifying various types of metal foreign objects and significantly improving detection coverage and accuracy. The Micron multi-frequency metal detector has four built-in frequencies, enabling simultaneous detection of any dual-frequency combination, automatically selecting the most appropriate detection frequency for each product, resulting in higher detection accuracy.

For example, when inspecting dry products, higher frequencies typically achieve greater sensitivity, especially for non-ferrous metals and stainless steel foreign objects. Therefore, when operating simultaneously in real-time, high- and low-frequency modes, the detection range can cover products of varying shapes and materials, achieving optimal results.

3. Product Effect

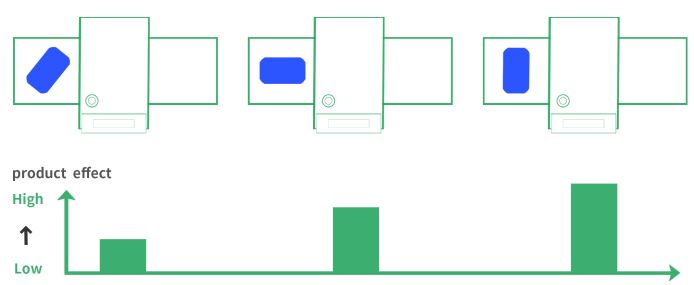

The product effect of a metal detector refers to the interference or influence that the characteristics of the inspected item (such as moisture, salt content, and temperature) can have on the detection results during operation. This influence can lead to decreased metal detection sensitivity, false alarms, or missed detections, and is a key technical challenge that needs to be addressed in the field of metal detector foreign object detection. As can be seen above, product effect, as an interference factor, can affect the sensitivity (and, in other words, detection accuracy) of metal detectors when performing food foreign body inspections. By flexibly utilizing product effect suppression algorithms and placing the object under inspection in the proper orientation during testing, product effect can be effectively suppressed and interference reduced. See the figure below for specific product feeding directions.

4. Position of the foreign object as it passes through the channel

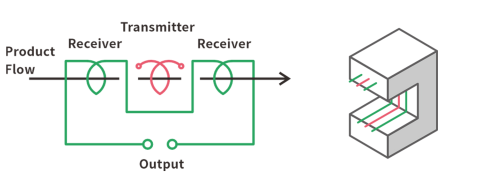

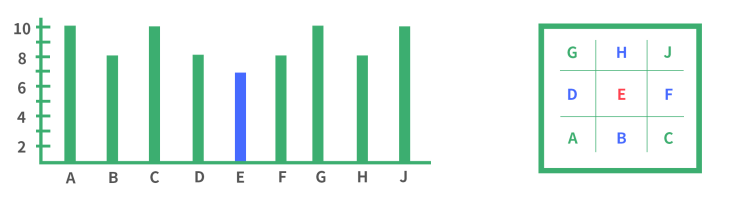

Currently, the coaxial metal detector, the most commonly used for food foreign body detection, has a balanced coil inside its probe that, in simple terms, surrounds the detection channel. As shown in the figure below:

Therefore, the sensitivity of a metal detector varies at different locations along the detection channel. As can be seen in the figure below, the center point E has the lowest sensitivity because it is farthest from the coil. Corners A, C, G, and J have the highest sensitivity because they are closest to the coils and lie at the angle between them. Therefore, they are most sensitive to magnetic field changes and, therefore, have the highest detection accuracy. Corners B, D, F, and H have the next highest accuracy.

Thus, when performing food foreign body inspections, it is best to choose areas with high sensitivity for the product to pass through to facilitate foreign body detection. However, it's important to note that when using a test piece for accuracy verification, it's important to try to pass through the center point E or a position close to it, as point E is the most challenging to detect. This results in a more accurate and precise measurement, helping to better understand the metal detector's true accuracy.

5. Type of Metal Foreign Object

When using a metal detector to inspect food for foreign objects, the type of metal foreign object significantly affects the detector's detection accuracy. Generally speaking, all other conditions remaining unchanged, food metal detectors have the highest sensitivity for ferrous foreign objects, while stainless steel has the lowest sensitivity.

The sensitivity of food metal detectors to different metal foreign objects varies significantly, primarily depending on the metal's physical properties. In terms of detection performance, ferrous magnetic metals have the highest sensitivity, thanks to their excellent magnetic permeability and electrical conductivity. When ferrous foreign objects pass through the detection area, they significantly alter the distribution of the electromagnetic field, generating a strong signal response. In contrast, stainless steel (especially non-magnetic stainless steel) has the lowest sensitivity, primarily due to its low magnetic permeability and relatively weak electrical conductivity. When conducting food foreign body inspections, food manufacturers need to select appropriate detection sensitivity based on the product's characteristics. This is especially true for products with high salt and moisture content, especially those with stainless steel. Using a multi-frequency metal detector can significantly reduce this problem.

Currently, multi-frequency metal detectors, by utilizing multi-frequency signal processing technology and intelligent algorithms, have significantly improved the ability to detect difficult-to-detect metals like stainless steel. However, variations in detection sensitivity due to physical properties still exist. The specific detection difficulty of different metals can be seen in the chart below:

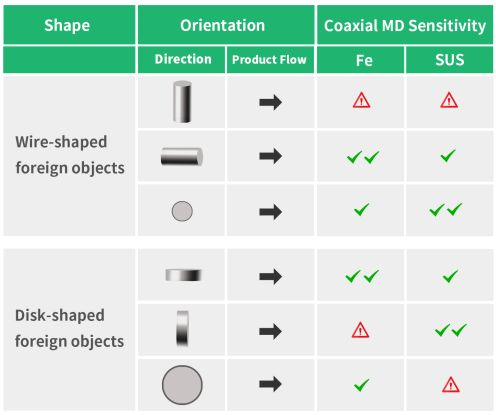

6. Foreign Object Shape and Orientation

When inspecting food for foreign objects, the shape and orientation of the metal object as it passes through the metal detector directly impacts detection sensitivity. This is because the metal detector's operating principle relies on electromagnetic induction. When a metal object passes through the detection zone, it cuts through magnetic field lines, generating eddy currents or magnetic field disturbances that are detected by the sensor. However, metal objects of varying shapes and orientations interfere with the magnetic field to varying degrees, causing variations in the detection signal strength and potentially affecting the final test results. Taking iron and stainless steel as examples, the impact of foreign body orientation and shape on metal detector accuracy is detailed in the figure below. Therefore, when conducting food foreign body inspections, it's important to consciously experiment with multiple orientations to achieve the most accurate foreign body detection rate possible.

7. Influence of the Product Being Inspected

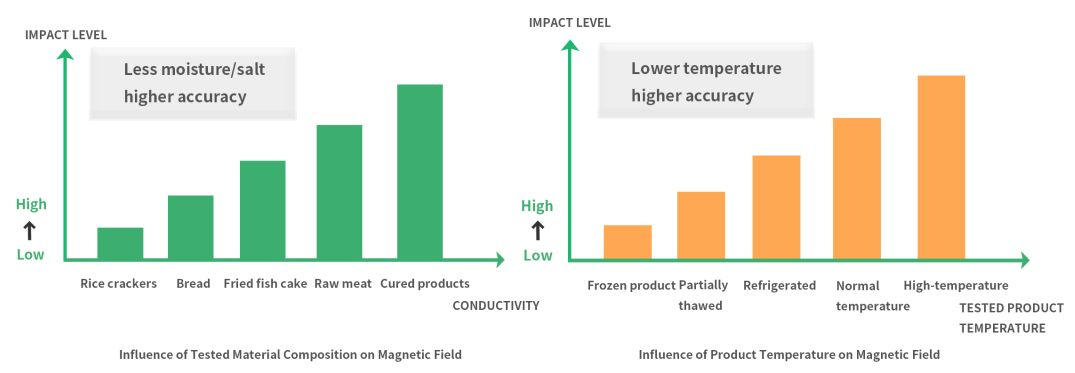

When inspecting food for foreign body defects, the product's humidity, salt content, and temperature are three key factors affecting the sensitivity of metal detectors. Changes in these parameters directly impact the accuracy of detection results.

First, the product's humidity (moisture content) significantly affects the sensitivity of the metal detector. When the product is drier, its conductivity is lower, which reduces signal interference from metallic foreign bodies. Therefore, the metal detector can more accurately identify tiny metallic impurities and achieve higher detection sensitivity. Conversely, when the product's moisture content is higher (such as in wet ingredients, sauces, or frozen-thawed food), its conductivity increases, which can easily generate metal-like signal interference, resulting in decreased detector sensitivity and the potential for false alarms or missed detections.

Second, the product's salt content also significantly affects detection performance. Salt increases the product's conductivity, making the metal detector more susceptible to interference during the inspection process. For example, low-salt or salt-free dry foods (such as flour and potato chips) generally achieve higher detection sensitivity. However, high-salt products (such as preserved foods, seasonings, and seafood) may reduce the detector's detection capabilities due to changes in conductivity caused by salt, making it more difficult to accurately detect even tiny metallic foreign objects.

Product temperature is also a factor that cannot be ignored. Generally speaking, the molecular activity of low-temperature products is slower, resulting in relatively stable conductivity. Therefore, detectors can maintain high detection accuracy when inspecting frozen or refrigerated products (such as frozen meat and ice cream). However, high-temperature products (such as freshly baked pastries and heat-processed meats) experience changes in conductivity due to increased temperature, which can generate additional signal noise, affecting the detector's stability and sensitivity and even causing false alarms.

In summary, to ensure optimal detection performance, the detector's parameters should be appropriately adjusted based on product characteristics (such as moisture and salt content, and temperature). If necessary, technical measures such as temperature compensation and product effect suppression can be employed to optimize detection accuracy.

8. Packaging Materials

Conductive packaging materials, such as aluminum foil, can significantly interfere with the sensitivity of metal detectors, making it difficult for conventional metal detectors to accurately identify metallic foreign objects in products.

Because aluminum foil itself generates an electromagnetic signal similar to that of metallic impurities, when such packaged products pass through the detection zone, the equipment is often strongly interfered with, resulting in a significant increase in false alarm rates or even complete failure to detect properly. Therefore, specially designed aluminum foil metal detectors are often used to inspect products with such special packaging.

When selecting metal detector equipment for food foreign object detection, it is important to fully consider the packaging characteristics of the product. Select the appropriate metal detector equipment.

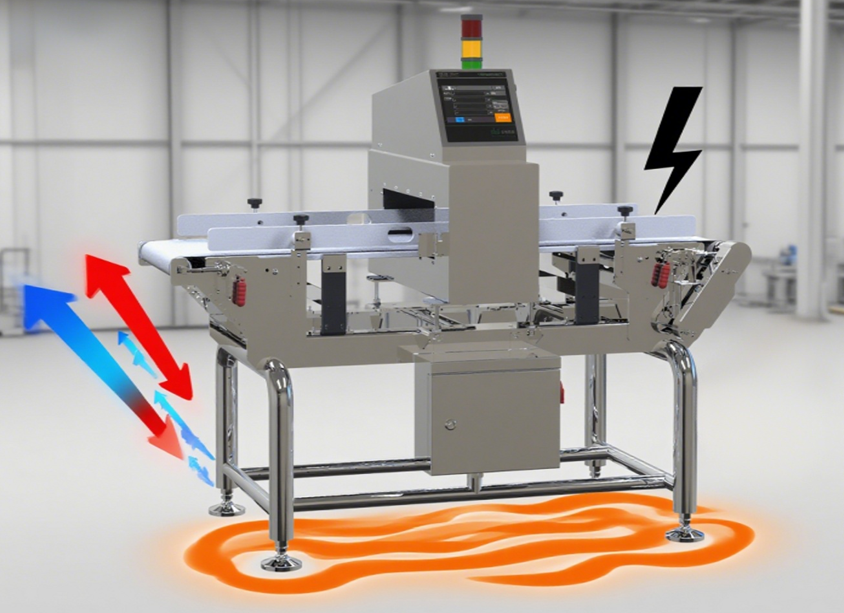

9. Environmental Factors

In actual industrial production environments, metal detectors may be subject to interference from a variety of external factors, affecting their detection accuracy and reliability. Mechanical vibration from the factory floor is one of the most common influencing factors. When equipment is installed near heavy machinery or in an area with high vibration on the production line, continuous mechanical vibration can cause micro-displacement or structural loosening of the metal detector's internal sensors, thereby affecting the stability of the detection signal. Especially in applications where high detection sensitivity is required, even micron-level vibration offsets can lead to skewed detection results. Temperature fluctuations can also affect the performance of metal detectors. In production workshops with large temperature swings between day and night, or on production lines that alternate between inspecting frozen foods and hot products, the electronic components within the metal detector will expand and contract due to temperature fluctuations, potentially causing problems with certain precision components. Furthermore, prolonged operation in extreme high and low temperature environments can accelerate equipment aging and shorten the lifespan of critical components.

Electromagnetic interference is another environmental factor that requires special attention. In modern industrial plants, large motors, inverters, welding equipment, high-frequency heating devices, and other devices generate strong electromagnetic noise. These interference sources can affect the normal operation of metal detectors through radiation from space or conduction through power lines. Especially when the interference frequency is close to the metal detector's operating frequency, it can cause false alarms or reduced sensitivity. Strong electromagnetic interference can even temporarily disable the detection system, resulting in serious consequences such as production line downtime.

To address these environmental challenges, modern metal detectors typically incorporate multiple protective measures, including enhanced mechanical structure design for vibration resistance, electromagnetic shielding, and optimized signal processing algorithms, to ensure stable detection performance in diverse and complex industrial environments.

http://www.vixdetect.net

vixdetect -

AuthorPosts

- You must be logged in to reply to this topic.