- This topic is empty.

-

AuthorPosts

-

11/06/2025 at 16:19 #3990

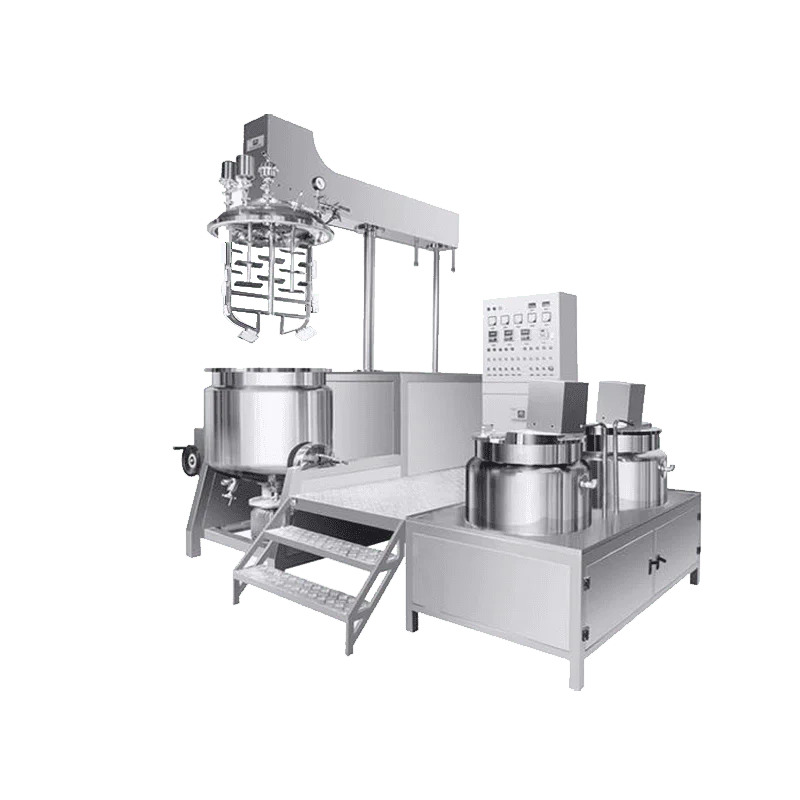

In today’s competitive manufacturing landscape, product consistency, processing efficiency, and hygienic standards are non-negotiable—especially in industries such as cosmetics, pharmaceuticals, food processing, and chemical production. One piece of equipment that plays a central role in meeting these requirements is the Bottom Vacuum Emulsifier Homogenizer Mixer.

These advanced mixing systems are designed to handle complex formulations involving emulsification, dispersion, homogenization, and vacuum deaeration, all in one streamlined process. In this article, we explore the key features that make bottom vacuum emulsifier homogenizer mixers essential for industrial use, and how companies like Orisun, a professional mechanical design and manufacturing firm, are helping clients customize and implement these high-performance systems.

What Is a Bottom Vacuum Emulsifier Homogenizer Mixer?

A bottom vacuum emulsifier homogenizer mixer is a type of industrial mixing equipment that combines high-shear homogenization with vacuum technology. The term "bottom" refers to the placement of the homogenizer at the base of the mixing tank, offering superior mixing efficiency and complete dispersion of ingredients from the bottom up.

This design is particularly useful when processing materials that are difficult to blend, dissolve, or emulsify, and ensures even distribution of active ingredients in products like creams, ointments, sauces, and detergents.

Top Features That Set These Mixers Apart

1. Bottom-Mounted High-Shear Homogenizer

Unlike top-mounted mixers, bottom homogenizers pull materials downward, creating a vortex that eliminates dead zones. This ensures faster mixing, better emulsification, and full dispersion of powders or viscous substances.

2. Integrated Vacuum System

The vacuum function removes air bubbles during mixing, which is essential for producing smooth, stable emulsions and high-gloss products. It also improves shelf life and product quality by preventing oxidation and contamination.

3. Efficient Heating and Cooling Jacket

The mixing vessel often comes with a double-jacketed design that allows precise temperature control. Whether melting waxes or cooling emulsions, this feature supports sensitive formulations that require controlled thermal processing.

4. Variable Speed Control

Frequency inverters or servo motors allow operators to adjust the mixing speed depending on the viscosity of the ingredients. This adaptability ensures that the mixer handles both low and high-viscosity products efficiently.

5. CIP/SIP Capability (Clean-In-Place/Sterilize-In-Place)

Hygiene is paramount in cosmetic and pharmaceutical manufacturing. These mixers are designed to meet sanitary standards and support automated cleaning and sterilization, reducing downtime and improving process safety.

6. User-Friendly Control Panel

Advanced mixers often feature a PLC touch screen interface, enabling precise control over time, temperature, speed, and vacuum level. Some models support recipe management, batch recording, and remote monitoring.

7. Modular Design for Customization

Many bottom vacuum emulsifier systems are modular, meaning they can be tailored to fit different production volumes, product types, and industry standards. Options include multiple mixing tanks, lifting systems, and inline homogenization.

Applications Across Industries

Bottom vacuum emulsifier homogenizer mixers are used in a wide range of sectors:

Cosmetics: Lotions, creams, gels, serums

Pharmaceuticals: Ointments, syrups, emulsions

Food & Beverage: Sauces, mayonnaise, flavor emulsions

Chemical: Detergents, coatings, lubricants

Their ability to perform multiple processes in one vessel reduces the need for additional equipment, minimizes product waste, and boosts overall production efficiency.

Orisun: Precision Engineering for Modern Manufacturing

As a company specializing in mechanical design and manufacturing, Orisun provides customized solutions for mixing, emulsification, and production automation. With years of experience in serving clients across pharmaceutical, food, and cosmetic sectors, Orisun understands that no two production lines are the same.

Their bottom vacuum emulsifier homogenizer systems are built to meet GMP standards and are fully configurable to client needs, including vessel size, mixing speed, material compatibility, and integration with upstream/downstream equipment. Orisun also offers on-site commissioning, training, and after-sales support, ensuring smooth implementation from design to operation.

Whether you’re upgrading an existing system or launching a new production line, Orisun’s engineering expertise and reliable equipment can give your business the edge in quality, efficiency, and compliance.

Final Thoughts

Investing in a bottom vacuum emulsifier homogenizer mixer is not just about mixing—it’s about transforming your production process into a more efficient, precise, and scalable system. With top features like high-shear homogenization, vacuum deaeration, thermal control, and intelligent automation, this equipment is a game-changer for modern manufacturing.

And with trusted partners like Orisun, you can be confident that your mixing solution is engineered for excellence.

Why Choose a Bottom Vacuum Emulsifier Mixer? Benefits for Industrial Formulations

-

AuthorPosts

- You must be logged in to reply to this topic.