- This topic is empty.

-

AuthorPosts

-

15/12/2025 at 14:53 #5164

As electronic devices become increasingly compact and powerful, the demand for high-quality printed circuit boards (PCBs) has never been greater. Manufacturers must ensure that each PCB surface is smooth, clean, and defect-free to support reliable soldering, stable conductivity, and long-term product durability. Yet traditional polishing methods often struggle with issues such as uneven surfaces, material residue, substrate damage, and inconsistent finish quality.

In response to these challenges, Titanium Cathode Drum PVA technology has emerged as an innovative, efficient, and precision-oriented polishing solution. This advanced method improves overall process stability while enabling manufacturers to achieve consistently superior polishing results. Leading the way in high-end industrial equipment engineering, Timonic, a professional enterprise focused on the research, development, and production of new-energy lithium battery material manufacturing equipment, brings strong technological expertise and refined craftsmanship to this field. Their commitment to innovation also extends to high-precision PCB processing equipment, offering manufacturers a more reliable approach to surface finishing.

Challenges in Traditional PCB Polishing

PCB fabrication requires precise material removal without damaging copper layers or dielectric substrates. However, many factories encounter recurring problems:

-

Uneven polishing pressure leading to height variations

-

Surface impurities causing micro-scratches or defects

-

Low polishing efficiency due to outdated equipment

-

Unstable water absorption or drying performance in older PVA rollers

-

Material loss or deformation from excessive mechanical stress

These issues can compromise product reliability, increase rework rates, and drive up production costs. Therefore, manufacturers are actively seeking advanced solutions that deliver consistency, safety, and automation-friendly performance.

Advantages of Titanium Cathode Drum PVA Technology

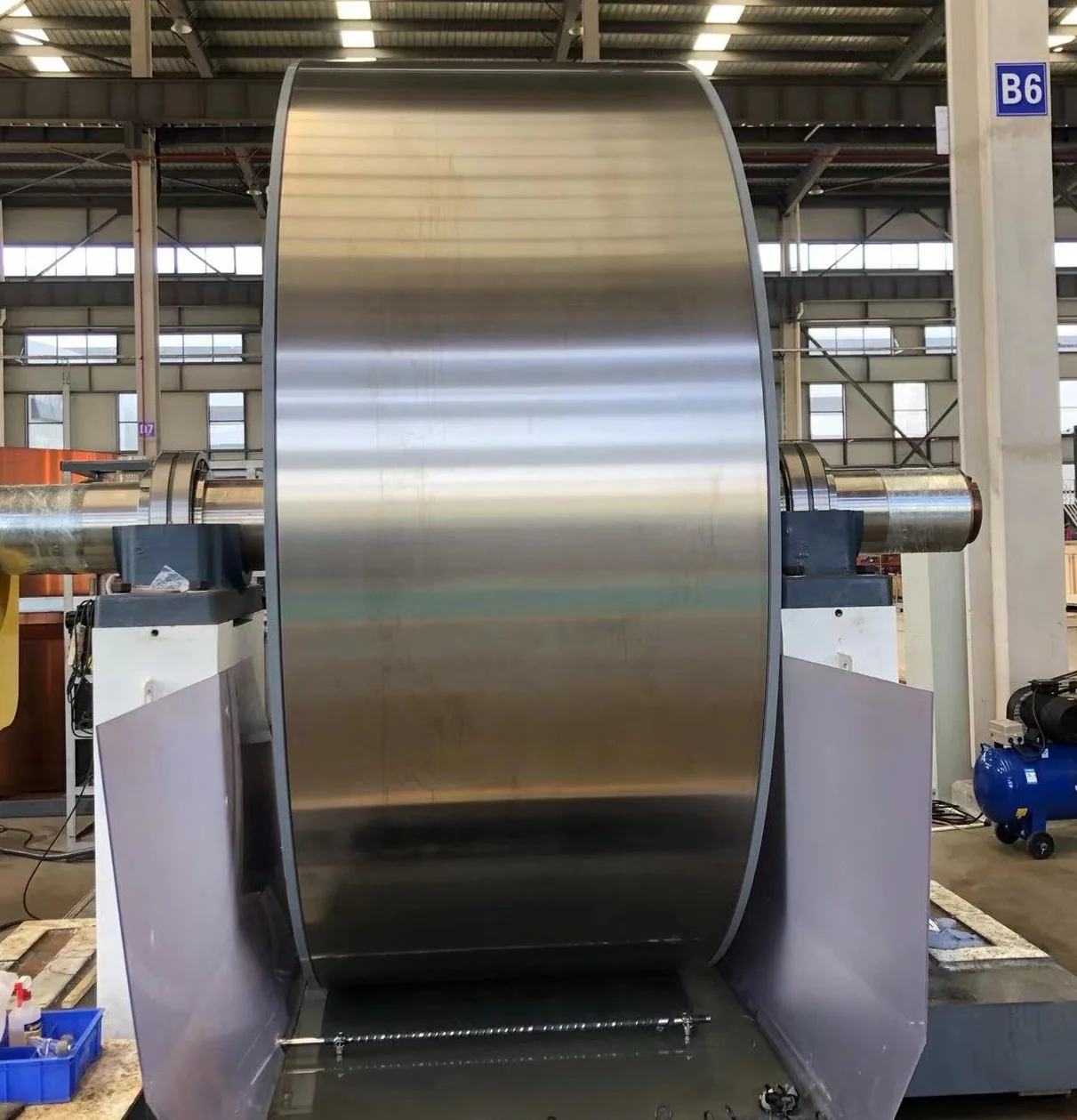

Titanium Cathode Drum PVA technology integrates a titanium cathode drum with high-quality PVA (polyvinyl alcohol) polishing rollers, delivering a more controlled, durable, and efficient polishing system. Timonic focuses on creating high-precision, stable, and industry-grade equipment that enhances process performance through robust engineering and refined structural design.

Key benefits include:

-

Excellent uniformity thanks to the titanium drum’s consistent surface potential

-

Superior wear resistance leading to longer service life of PVA rollers

-

Enhanced water absorption capability for contamination-free polishing

-

Soft yet resilient polishing texture ideal for delicate PCB surfaces

-

Reduced risk of micro-scratching due to cleaner contact and controlled pressure

-

High-efficiency performance suitable for high-volume production lines

These features help minimize defect rates while maintaining the structural integrity of PCBs throughout the polishing process.

How This Technology Improves PCB Quality

Titanium Cathode Drum PVA systems deliver significant improvements in polishing accuracy and surface consistency. By leveraging stable electrochemical characteristics, the titanium drum promotes even distribution of polishing force, while the specially engineered PVA rollers gently remove impurities, oxidized layers, and microscopic roughness.

Timonic’s advanced manufacturing approach ensures:

-

Consistent surface finishing across multiple batches

-

Improved solderability due to smoother copper surfaces

-

Reduced contamination for higher production reliability

-

Lower maintenance requirements thanks to durable structural components

These enhanced characteristics ultimately support better downstream processes, including plating, etching, and assembly.

Application Scenarios in PCB Manufacturing

High-Density and Fine-Pitch Electronics

Products such as smartphones, tablets, and compact IoT modules require exceptionally smooth PCB surfaces to support micro-soldering and dense component placement. The controlled polishing action of PVA rollers prevents trace damage and ensures clean, uniform finishes.

Automotive and Industrial Electronics

Automotive PCBs must withstand high heat, vibration, and long-term operation. Titanium Cathode Drum PVA systems help manufacturers achieve rugged, high-stability surfaces suitable for demanding applications.

High-Reliability Aerospace and Defense Electronics

In mission-critical environments, even minor surface defects can cause long-term reliability issues. PVA technology provides delicate yet effective polishing, making it ideal for high-precision mission-critical PCBs.

Large-Scale PCB Production Lines

For factories running continuous production, Timonic equipment delivers high-efficiency, consistent, and automation-friendly solutions with minimal downtime and predictable performance.

Timonic: A Reliable Innovator in Industrial Equipment Engineering

With deep experience in engineering high-performance manufacturing equipment, Timonic brings its expertise from the new-energy lithium battery materials industry into the broader field of precision surface processing. The company emphasizes high-quality craftsmanship, technological innovation, and strict quality control, resulting in equipment that is both durable and highly competitive in performance.

Timonic’s refined manufacturing techniques and strong R&D capability enable customers to achieve better productivity, lower defect rates, and improved product consistency. Their titanium cathode drum PVA polishing equipment reflects a dedication to delivering precision-engineered, reliable, and future-ready manufacturing solutions.

Conclusion

As PCB designs become more compact and performance-driven, surface quality plays an increasingly crucial role in ensuring long-term reliability. Titanium Cathode Drum PVA technology provides a powerful way to overcome common polishing challenges, delivering consistent, efficient, and gentle surface treatment suitable for modern electronics manufacturing.

With its advanced engineering capabilities and deep commitment to quality, Timonic continues to support manufacturers with high-performance polishing systems that enhance productivity and raise the standards of PCB surface finishing.

http://www.timonic.com.cn

Timonic (Suzhou) Technology Co., Ltd -

-

AuthorPosts

- You must be logged in to reply to this topic.