- This topic is empty.

-

AuthorPosts

-

19/12/2025 at 22:02 #5178

https://www.goldenabrasives.com/waterproof-sandpaper-the-key-to-precision-sanding-and-perfect-surfaces.html

https://www.goldenabrasives.com/Waterproof-abrasive-paper

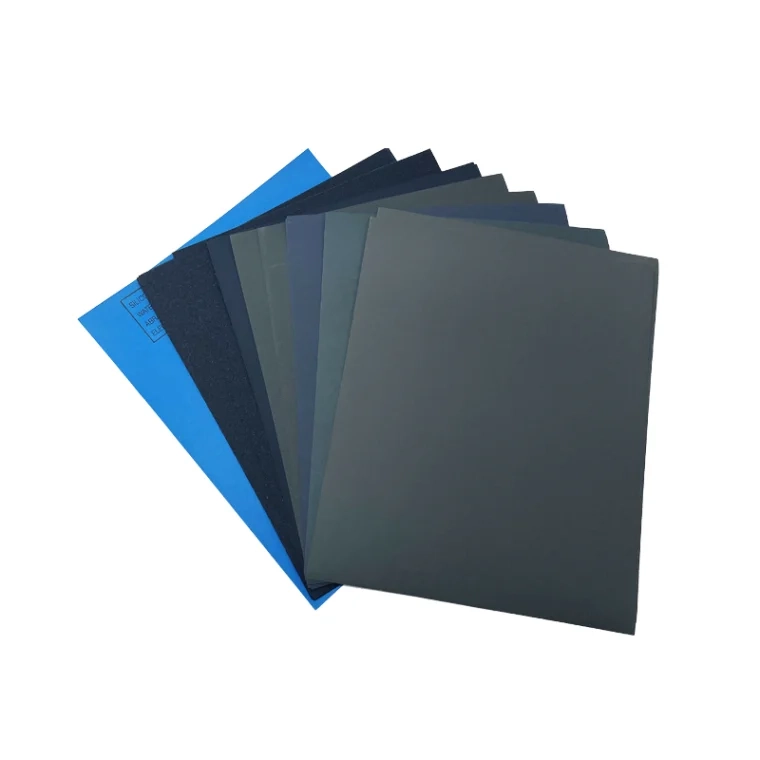

Waterproof sandpaper is a crucial tool for achieving precise, controlled surface finishes in various industries, particularly where smooth, high-quality results are required. While it's well-known for its ability to withstand moisture, what truly sets waterproof sandpaper apart is its carefully engineered structure and its abrasive grains, which perform differently depending on the material being worked on and the sanding conditions. This article Golden Abrasives delves into two important aspects of waterproof sandpaper: its structure and the cutting behavior of different abrasive grains when used in wet sanding applications.

The Structure of Waterproof Sandpaper: Essential Components

The structure of waterproof sandpaper is designed to deliver superior performance in wet sanding applications, where water or lubricants play a critical role in enhancing the abrasive process. Understanding the components of waterproof abrasive paper is crucial for selecting the right type for specific applications.

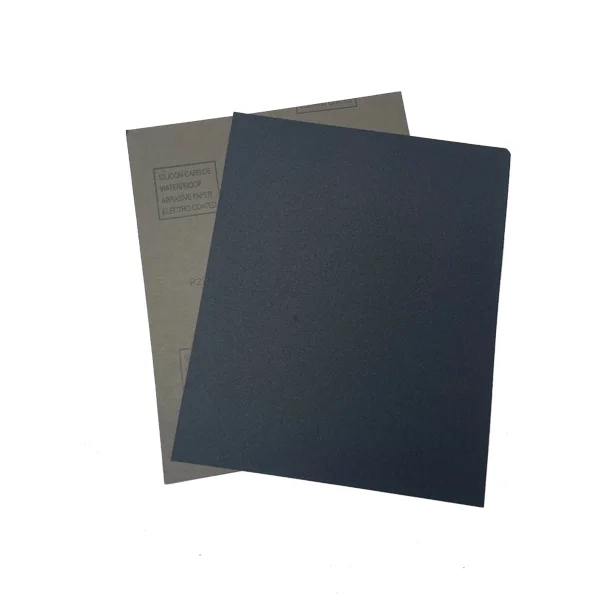

Water-Resistant Backing Material

The backing material of waterproof sandpaper serves as the foundation that holds the abrasive grains in place and provides durability and flexibility. Typically, two types of backings are used:

Latex Paper Backing

Latex paper is highly flexible and tear-resistant, making it ideal for tasks that require conformity to curved or irregular surfaces. This type of backing ensures that the sandpaper can bend and wrap around edges without losing its effectiveness. When soaked in water, latex paper does not disintegrate or lose its shape, allowing the abrasive to maintain its contact with the surface.

Resin Bonding

The resin bonding system is a key element that contributes to the durability and water-resistance of waterproof sandpaper. The resin ensures that the abrasive grains are securely attached to the backing material, even under wet conditions. It also prevents the grains from falling off during use, which is especially important for wet sanding, where the abrasive action can cause grain loosening and detachment.

Abrasive Grains

The choice of abrasive grains significantly impacts the cutting action and surface finish achieved by waterproof sandpaper. Two common abrasive grains used in waterproof sandpaper are silicon carbide and aluminum oxide. These materials are selected for their hardness, sharpness, and durability under wet sanding conditions.

-

Silicon Carbide: Known for its sharp, angular grains, silicon carbide is ideal for fine finishing, providing a smoother surface and better results when sanding delicate materials like automotive paint or wood finishes. The grains tend to fracture during use, which ensures the abrasive maintains its cutting ability for longer.

-

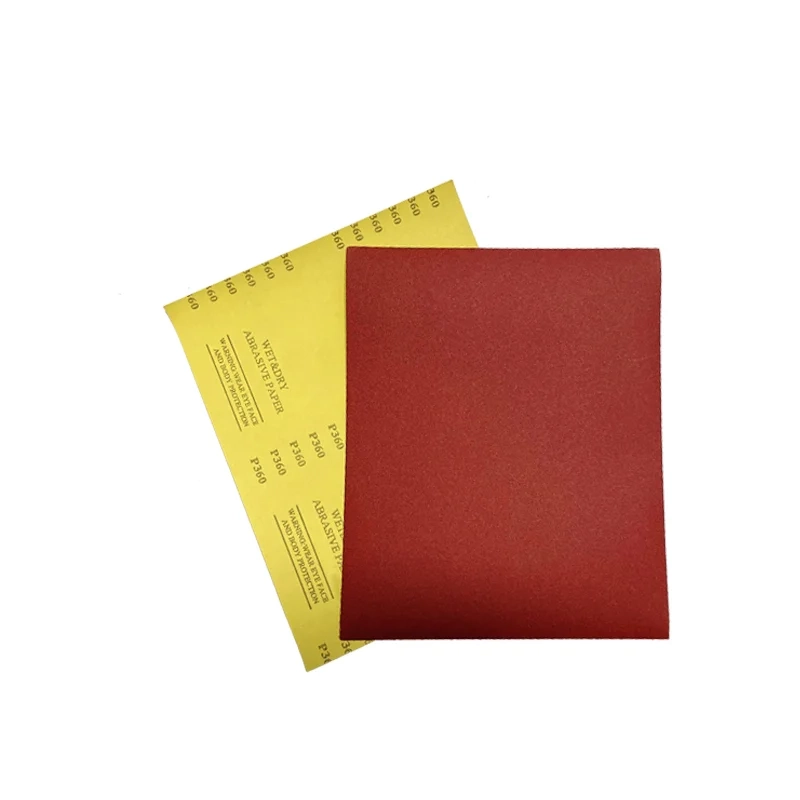

Aluminum Oxide: While aluminum oxide is more commonly used for dry sanding, it is also used in waterproof sandpaper for applications that require heavier cutting and longer life. It is a tougher material, resistant to wear, and is ideal for tasks that require fast material removal.

Golden Abrasives waterproof sandpaper incorporates a variety of bonding techniques and abrasive materials to enhance its performance in both professional and industrial applications. The precise blend of silicon carbide and resin ensures longevity, high performance, and minimal grain shedding during wet sanding tasks.

Cutting Behavior of Abrasive Grains in Waterproof Sandpaper

The cutting behavior of waterproof sandpaper is largely influenced by the type of abrasive grain it contains. Different abrasives have varying characteristics that affect the cutting process, particularly when water is used as a lubricant. Let's explore the cutting behavior of silicon carbide and aluminum oxide grains in wet sanding environments.

Silicon Carbide: Sharp and Aggressive Cutting Action

Silicon carbide waterproof sandpaper is favored for its sharp edges and angular structure. In wet sanding, the sharpness of silicon carbide grains delivers an aggressive cutting action, making it ideal for finer sanding tasks and materials that require delicate abrasion.

In a wet sanding scenario, the lubricating effect of water plays a critical role in preventing clogging. As the silicon carbide grains are exposed to moisture, the water helps to reduce friction, preventing the sandpaper from overheating and extending its useful life. This is especially beneficial when sanding materials like automotive paint, plastics, and ceramics, where maintaining a fine finish is essential.

The fracturing nature of silicon carbide grains also means that they continuously create new cutting edges throughout the sanding process. This self-sharpening characteristic makes silicon carbide particularly effective for maintaining consistent cutting performance over time.

Aluminum Oxide: Tough and Resilient for Heavier Cutting

Aluminum oxide is another commonly used abrasive in waterproof sandpaper. While silicon carbide excels in fine finishes, aluminum oxide is better suited for applications that require heavier cutting action. It is often preferred for removing material quickly or for sanding tougher surfaces like metals and hardwoods.

When used in wet sanding, aluminum oxide grains benefit from the cooling effect of water. The coolant properties of water help prevent the abrasive from overheating, allowing it to maintain its cutting efficiency without becoming dull too quickly. The abrasive wears more slowly than silicon carbide, making it suitable for tasks that involve prolonged sanding, such as smoothing rough wooden surfaces or preparing metal parts for painting.

Comparison: Performance in Wet Sanding

The cutting behavior of both silicon carbide and aluminum oxide in waterproof sandpaper depends on factors such as grit size, water lubrication, and the specific material being sanded. Silicon carbide tends to perform better in terms of surface finish quality due to its sharpness and self-sharpening characteristics, making it ideal for applications that require a high degree of smoothness. In contrast, aluminum oxide is better for aggressive material removal and durability over extended sanding periods.

Silicon Carbide: Best for fine finishing and delicate materials like glass, automotive paint, and soft woods.

Aluminum Oxide: Suitable for coarse sanding and tougher materials like metals and hardwoods.

Conclusion

Waterproof sandpaper is designed to offer precise and controlled surface finishing in wet sanding applications. Its structure, which includes a flexible yet durable backing, moisture-resistant resin bonding, and sharp abrasive grains, enables it to perform efficiently under wet conditions.

The cutting behavior of different abrasive grains—silicon carbide for fine finishes and aluminum oxide for heavy material removal—ensures that waterproof sandpaper can be tailored to the specific needs of the project at hand. The water used in the wet sanding process enhances the cutting efficiency by cooling the abrasive grains, reducing friction, and allowing for a cleaner finish.

By choosing the right waterproof sandpaper based on the desired cutting action and surface finish, professionals can achieve consistent, high-quality results. Golden Abrasives waterproof sandpaper, with its durable structure and carefully selected abrasive grains, offers reliable performance for a variety of sanding tasks, ensuring that each project achieves the best possible finish.

http://www.goldenabrasives.com

China Golden Abrasives -

-

AuthorPosts

- You must be logged in to reply to this topic.