- This topic is empty.

-

AuthorPosts

-

20/11/2025 at 15:09 #4971

In the field of modern mechanical engineering, precision, efficiency, and reliability are essential to producing high-quality gear systems. Among the many gear-cutting techniques, worm gear hobbing has become a key process for manufacturing precise and durable worm gears used across industries such as automotive, robotics, and industrial machinery. This advanced machining method not only ensures exceptional gear accuracy but also greatly enhances production efficiency.

What Is Worm Gear Hobbing?

Worm gear hobbing is a machining process that uses a specially designed cutting tool, known as a hob, to shape the teeth of a worm wheel. The process involves continuous and synchronized rotation between the hob and the workpiece, allowing for efficient and precise cutting of helical gear teeth. Compared with traditional gear shaping, hobbing offers higher productivity, smoother surface finish, and greater flexibility for different gear types.

The Efficiency Advantage of Worm Gear Hobbing

Worm gears are widely used in applications requiring high torque and compact design, such as gearboxes, lifting equipment, and automotive systems. The hobbing process plays a vital role in improving both the performance and efficiency of these gears in several ways:

-

High Precision and Consistency

CNC-controlled worm gear hobbing machines ensure micron-level accuracy, minimizing deviations and ensuring uniform tooth geometry. This leads to smoother transmission and less mechanical wear. -

Faster Production Cycles

Modern hobbing machines integrate high-speed spindles and advanced automation, enabling faster machining times compared to conventional gear cutting methods. This results in reduced production costs and improved throughput. -

Enhanced Surface Quality

The continuous cutting motion of the hob produces a superior surface finish, reducing friction losses in gear operation and improving overall transmission efficiency. -

Improved Tool Life and Stability

With optimized cutting parameters and high-rigidity designs, modern hobbing machines maintain stability even at high cutting speeds, extending tool life and ensuring consistent performance.

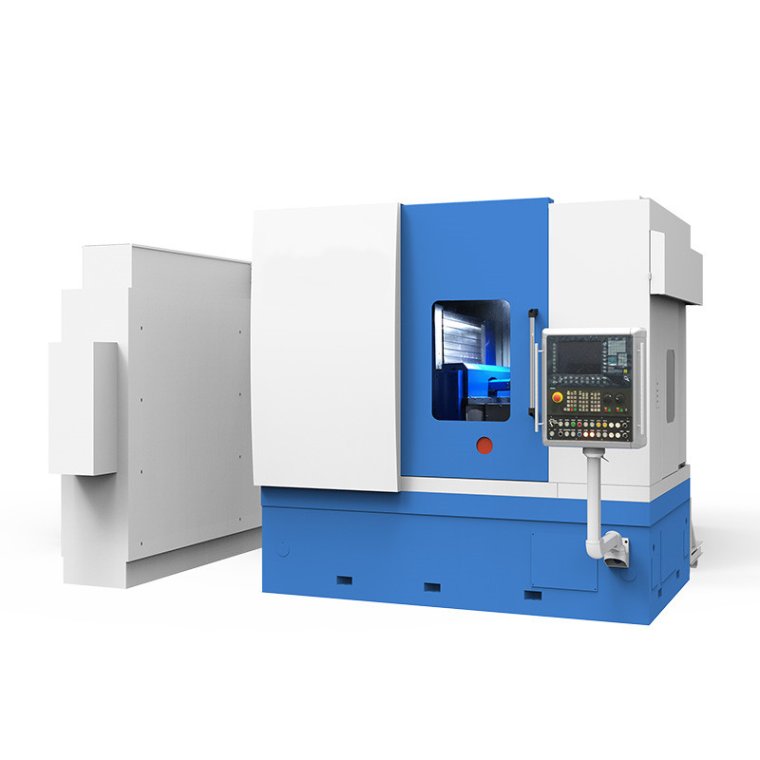

GLT Machinery: Driving Innovation in Worm Gear Hobbing

GLT Machinery (GLTM/GLT) is a leading CNC gear hobbing machine manufacturer in China, dedicated to developing high-speed, high-efficiency, and high-rigidity hobbing solutions. The company’s machines are designed with the latest automation and digital control technologies, ensuring superior precision and long-term reliability.

GLT Machinery’s solutions have been successfully applied in automotive, motorcycle, gearbox, timing pulley, and pump industries, helping manufacturers improve gear quality, reduce energy consumption, and increase overall production efficiency. Their advanced worm gear hobbing technology reflects a deep understanding of the evolving needs of modern mechanical engineering.

The Future of Gear Manufacturing

As industries move toward smarter and more energy-efficient production systems, CNC worm gear hobbing will continue to play a key role in the transformation of mechanical engineering. With innovations in digital manufacturing, real-time monitoring, and intelligent tool management, the next generation of hobbing machines will deliver even higher accuracy and automation capabilities.

Conclusion

Worm gear hobbing represents a perfect balance between precision, performance, and productivity. By integrating advanced hobbing technology from trusted manufacturers such as GLT Machinery, companies can achieve superior gear quality, longer product life, and higher operational efficiency — essential advantages in today’s competitive manufacturing landscape.

http://www.gltmachinery.com

Wuxi General Machinery Co., Ltd. (GLTM / GLT) -

-

AuthorPosts

- You must be logged in to reply to this topic.