- This topic is empty.

-

AuthorPosts

-

20/11/2025 at 15:18 #4992

In the modern manufacturing industry, mold maintenance and cleanliness play a pivotal role in ensuring product quality, extending mold life, and reducing downtime. One of the most critical aspects of mold upkeep is the cleaning of water channels, which are prone to scaling, residue buildup, and corrosion. Selecting the right mold water channel cleaning machine can dramatically improve efficiency, reduce maintenance costs, and maintain consistent product quality.

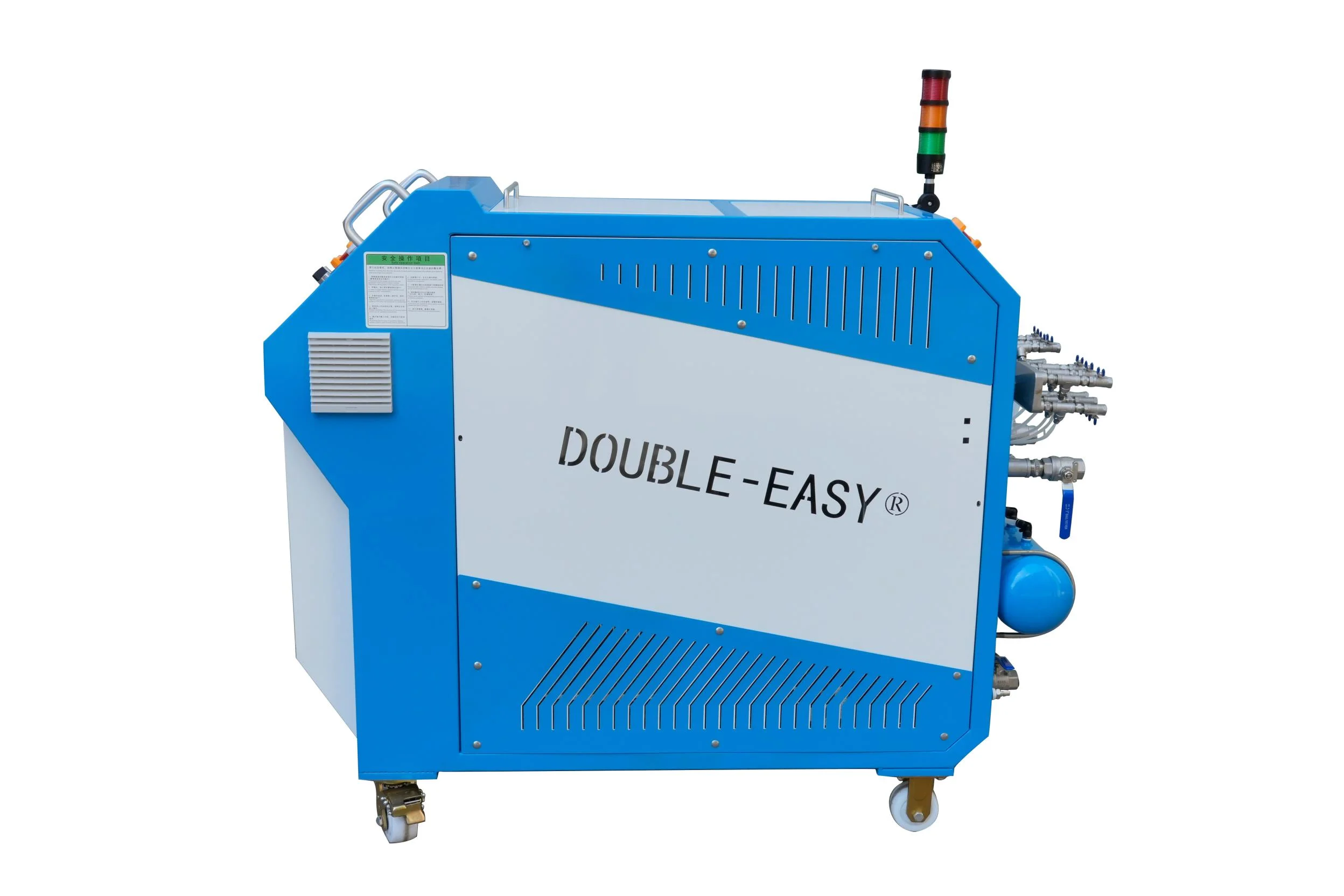

Guangzhou Yizai Intelligent Technology Co., Ltd. is a high-tech enterprise integrating research, development, production, sales, and service. Specializing in mold water channel cleaning machines, dry ice cleaning machines, laser cleaning systems, ultrasonic electrolysis cleaners, circulating water electronic pulse descaling machines, and DBAI energy management systems, Yizai provides comprehensive solutions for industrial cleaning needs.

1. Understand Your Mold Cleaning Requirements

Before choosing a cleaning machine, it’s essential to analyze your specific manufacturing and mold requirements:

-

Mold type: injection molds, die-casting molds, or extrusion molds.

-

Channel complexity: straight channels vs. intricate geometries.

-

Residue type: mineral scale, rust, plastic residues, or lubricant buildup.

-

Cleaning frequency and production volume: high-volume production may require faster or automated cleaning solutions.

Understanding these parameters ensures you select a machine that meets your operational demands while protecting the integrity of your molds.

2. Key Types of Mold Water Channel Cleaning Machines

Guangzhou Yizai Intelligent Technology offers several innovative cleaning solutions:

-

Mold Water Channel Cleaning Machines – Specifically designed for removing scale, rust, and residues inside mold cooling channels efficiently.

-

Ultrasonic Electrolysis Cleaning Machines – Use high-frequency ultrasonic waves and electrolysis to clean intricate channels without damaging the mold.

-

Dry Ice Cleaning Machines – Non-abrasive and eco-friendly, ideal for surface cleaning without introducing moisture.

-

Laser Cleaning Machines – Provide precise, contact-free cleaning for sensitive molds or delicate surfaces.

-

Circulating Water Electronic Pulse Descaling Machines – Use electronic pulses to prevent scaling in mold water channels during production.

Each machine type is tailored to different cleaning challenges, allowing manufacturers to select a solution that matches their specific mold design and production workflow.

3. Consider Efficiency and Automation

In high-volume manufacturing, efficiency and automation are key. Machines with automated cycles, programmable cleaning modes, and rapid setup reduce manual labor, minimize downtime, and improve consistency.

Yizai’s mold water channel cleaning machines are designed with automation and energy efficiency in mind, allowing operators to clean multiple molds simultaneously with minimal supervision, while ensuring uniform cleaning performance across all channels.

4. Material Compatibility and Mold Protection

It’s critical that the cleaning process does not damage mold surfaces. Machines should be compatible with:

-

Stainless steel, aluminum, or other mold metals

-

Sensitive coatings or surface treatments

-

Complex channel geometries

Guangzhou Yizai Intelligent Technology emphasizes precision engineering and gentle yet effective cleaning mechanisms, protecting mold integrity while thoroughly removing scale, rust, and residue.

5. Energy Efficiency and Sustainability

Modern manufacturers are increasingly focused on energy savings and environmental impact. Yizai’s DBAI energy management systems and optimized cleaning machines reduce electricity and water consumption, ensuring cost-effective and sustainable operations.

Additionally, non-toxic cleaning methods such as dry ice or ultrasonic cleaning minimize chemical waste and reduce environmental hazards, aligning with green manufacturing practices.

Conclusion

Choosing the right mold water channel cleaning machine is vital for ensuring mold longevity, maintaining product quality, and reducing operational downtime. Factors to consider include cleaning requirements, mold type, channel complexity, material compatibility, automation features, and energy efficiency.

Guangzhou Yizai Intelligent Technology Co., Ltd. provides a comprehensive range of advanced cleaning solutions tailored for diverse manufacturing needs. From ultrasonic electrolysis and dry ice cleaning to circulating water descaling and laser cleaning systems, Yizai ensures manufacturers have the right tools for precise, efficient, and sustainable mold maintenance.

Investing in the proper cleaning machine not only preserves your molds but also enhances production reliability, operational efficiency, and long-term cost savings, making it an essential consideration for any modern manufacturing facility.

http://www.moldcleanmachine.com

Guangzhou Yizai Intelligent Technology Co., Ltd -

-

AuthorPosts

- You must be logged in to reply to this topic.