- This topic is empty.

-

AuthorPosts

-

10/07/2025 at 17:44 #4230

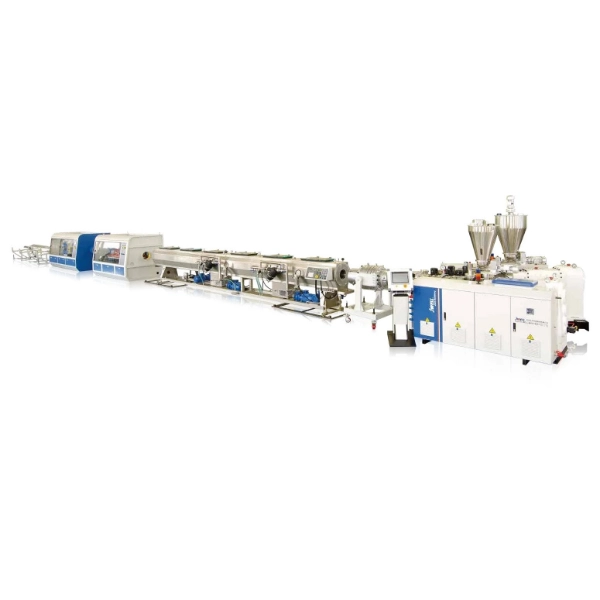

PVC (Polyvinyl Chloride) solid wall pipes are widely used across various infrastructure, construction, and industrial sectors due to their superior corrosion resistance, strength, and cost-effectiveness. The production of these pipes demands advanced and reliable machinery to ensure consistent quality, high throughput, and energy efficiency. JWELL Machinery, a globally recognized plastic extrusion machinery manufacturer, plays a crucial role in this segment with its highly engineered extruder systems. This article will share JWELL extruder in PVC solid wall pipe manufacturing, its advantages and performance characteristics.

1. Overview of PVC Solid Wall Pipe Manufacturing

PVC solid wall pipes are monolithic pipes with uniform wall thickness, commonly used for potable water distribution, sewage, drainage, cable ducting, and industrial piping systems. The manufacturing process primarily involves:

* Material feeding and melting

* Plasticizing and homogenizing

* Extrusion through a pipe die

* Vacuum calibration and cooling

* Haul-off (traction) and cutting

To maintain pipe dimensional stability, mechanical strength, and smooth surface finish, the extrusion line must operate under tight process control. This is where JWELL extruders offer a competitive edge through their precision engineering and process automation.

2. JWELL Extruder Configuration for PVC Solid Wall Pipes

JWELL offers several types of extruder configurations tailored for PVC applications:

* Conical Twin-Screw Extruder

Ideal for processing rigid PVC formulations, this extruder type features a large L/D ratio and strong shear capabilities, which ensure uniform mixing and plastification. The conical screw design enables stable output at lower screw speeds, reducing shear heating and degradation.

* Parallel Twin-Screw Extruder

Suitable for high-output operations, parallel twin-screw extruders from JWELL offer better energy efficiency and scalability for larger-diameter PVC pipe production.

These extruders are typically integrated into a complete extrusion line that includes a mold/die head, vacuum calibration tank, spray cooling tank, haul-off unit, cutter, and stacker.

3. Key Applications of JWELL Extruder in PVC Solid Wall Pipe Manufacturing

3.1 Municipal Water Supply and Drainage Systems

JWELL extruders are widely used in producing pipes for municipal water supply and drainage systems. PVC pipes made with JWELL machinery are characterized by:

* Excellent dimensional accuracy

* High resistance to internal pressure

* Low coefficient of friction for better flow characteristics

* UV stabilization for outdoor installation

The use of precision screw design and automatic control systems ensures consistent material melting and homogeneous mixing, which are critical for pipes subjected to fluctuating hydraulic loads.

3.2 Electrical Cable Conduits

PVC solid wall conduits used in electrical installations require smooth inner surfaces, controlled wall thickness, and precise diameters to ensure easy cable pulling and installation. JWELL' s extrusion lines deliver these specifications reliably. Advanced control panels monitor critical parameters like melt pressure, barrel temperature, and screw torque to avoid surface defects and maintain tight tolerances.

3.3 Sewage and Wastewater Systems

In sewage infrastructure, PVC solid wall pipes need to resist corrosion from biological and chemical agents. JWELL extruders allow for the incorporation of additives such as anti-microbial agents, plasticizers, and stabilizers during the extrusion process. The extrusion temperature profile and screw compression ratio can be adjusted to accommodate different PVC compounds without sacrificing pipe integrity.

3.4 Agricultural Irrigation Pipelines

For agricultural applications, PVC pipes must withstand exposure to sunlight, fertilizers, and fluctuating pressures. JWELL' s extruders enable the production of UV-resistant and pressure-rated pipes, with surface finishes that minimize sediment buildup. Optional co-extrusion features allow manufacturers to produce pipes with colored outer layers for product identification and enhanced UV protection.

3.5 Industrial Chemical Piping

JWELL extruders are utilized to produce PVC pipes used in transporting mild chemicals in industrial settings. These applications require pipes with excellent chemical resistance, mechanical durability, and thermal stability. The extruder' s capability to process rigid and chlorinated PVC (CPVC) compounds makes it ideal for such demanding applications.

4. Technical Highlights of JWELL Extruders

4.1 Advanced Screw and Barrel Design

JWELL employs specialized screw profiles and barrel grooving that enhance plasticizing efficiency and increase output. The conical twin-screw setup ensures:

* Efficient feeding and degassing

* Uniform shear distribution

* Optimized temperature control along the barrel

These characteristics are essential for minimizing unplasticized particles and preventing thermal degradation, both of which can compromise pipe performance.

4.2 High Automation and Intelligent Control

JWELL extruders come equipped with advanced Siemens or ABB PLC control systems featuring:

* Closed-loop feedback for pressure and temperature regulation

* Real-time monitoring and diagnostics

* Recipe management for different PVC grades

Such automation reduces operator dependency, increases repeatability, and ensures stable operation across shifts and production batches.

4.3 Energy Efficiency and Cost Savings

Energy efficiency is a key focus of JWELL' s engineering. Features contributing to reduced energy consumption include:

* AC motor drives with high power factor

* Optimized heater band insulation

* Precise temperature zoning to avoid overheating

Additionally, the use of bimetallic barrels extends service life, reducing maintenance costs.

4.4 Die Head and Calibration Unit Integration

JWELL' s proprietary spiral-type die heads ensure uniform melt distribution, resulting in pipes with minimal wall thickness deviation. The vacuum calibration tank and spray cooling tank are engineered for fast cooling, enabling higher line speeds without sacrificing dimensional accuracy. The calibration sleeve can be customized for various pipe diameters and wall thicknesses.

5. Customization and Modularity

JWELL extruders offer high levels of customization. Manufacturers can specify:

* Output capacity (kg/h) based on target diameter range

* Single or dual-strand extrusion for increased productivity

* Inline co-extrusion capability for multilayer pipes

* Custom screw geometry based on formulation

This modularity allows PVC pipe producers to tailor their extrusion line to their exact needs and market requirements.

6. Compliance and Global Standards

JWELL extruder systems and extrusion lines are built in accordance with international safety and performance standards, including:

* CE certification for European markets

* ISO 9001 for quality assurance

* UL standards for electrical components (upon request)

This makes JWELL extruders suitable for global deployment in regulated environments, particularly in civil infrastructure projects and utility networks.

7. Practical Outcomes and Industry Testimonials

Across Asia, Europe, and the Americas, pipe manufacturers using JWELL extruders have reported:

* 10–20% increase in line throughput

* Reduction in raw material waste due to stable processing

* Fewer product defects and lower rejection rates

* Improved product traceability and quality control

These outcomes validate JWELL' s investment in R\&D and its commitment to continuous improvement.

Conclusion

The applications of JWELL extruders in PVC solid wall pipe manufacturing span a wide range of infrastructure, industrial, and utility sectors. Their robust design, technical precision, and process flexibility make them an indispensable tool for manufacturers aiming for high output, consistent quality, and operational efficiency. Whether for water supply, sewage systems, electrical conduits, or chemical pipelines, JWELL extruder systems deliver the performance and reliability that today' s competitive PVC pipe market demands.

http://www.jwellplas.com

JWELL -

AuthorPosts

- You must be logged in to reply to this topic.